Restoration of Westland Wessex 60, G-AVNE

Wessex 60 HistoryWestland built sixteen Wessex 60s, based on the RAF's HC.2 model, for Bristow Helicopters, between 1965 and 1975, to replace some of the Widgeons and Whirlwinds in their fleet, which serviced the expanding UK and overseas offshore oil and gas exploration sector.The seventh Westland Wessex Series 60 to be built, G-AVNE, Con.No. WA/561, a 16 passenger civil transport with twin 1350 shp Rolls-Royce Gnome H1200, Mk.660, turboshaft engines, was delivered to Bristow, at Redhill, in 1967. It was the first long-range Series 60 and, soon after delivery, was despatched to Sunderland, N.E. England, where it operated in support of one of the early offshore oil rigs, 'Glomar IV'. |

|

|

| In 1970 G-AVNE was flown out, from the UK, to Kuantan, in Malaysia, and transferred to Bristow's Far East operations, serving successively in Singapore, Indonesia, Australia and then back in Malaysia, each time with appropriate re-registration. It returned to the UK in 1973. | ||

| In 1974 G-AVNE was transferred

to the Warri base in Nigeria, again to support offshore oil rigs

and platforms. It was re-registered as 5N-AJL and remained in Nigeria

until 1981 when, following a third and serious accident to a Wessex

60, it was withdrawn from service and returned, via Redhill, to

the Westland factory in Weston-super-Mare. In 1987, after three years in hangar storage at Hurn Airport near Bournemouth, G-AVNE was bought by The Helicopter Museum for outdoor static display at the Museum (right), which, at that time, was sited adjacent to the Westland factory in Weston-super-Mare. |

|

|

Wessex 60 Restoration |

||||

|

|

|

||

| G-AVNE remained on outdoor static display until 2001 when it was brought into the then newly-built Display Hangar. On 12th January 2008 it was rolled into the new Conservation & Engineering Hangar (above left) with its restoration entrusted to Mike Reading's team, while they were still nearing completion of their work on Westland Whirlwind HAR.10, XD163. An unexpected delay in the completion of XD163 meant that work on G-AVNE didn't start until 23rd February, when the nose-mounted debris filter was removed (above centre) and the erection of staging was started (above right), to allow safe access to the main rotor head and gearbox. | ||||

|

By early March 2008 the usual

structural survey had started. Corrosion was found to be widespread

though often superficial. Severe corrosion was evident in a few of the

airframe skin panels and a number of these were listed for replacement.

Some of the alloy rivet heads were in a very poor condition and many

steel nuts and bolts were rusted (left). The folded main rotor blades were removed, on 29th March 2008, and this task was made easier with the use of a puller tool to extract the securing taper pins which were corroded. It was fortunate that, with the main blades having been displayed in their folded state for many years, only some of the pins were still in place. The tail rotor blades had been easily detached after a few weeks soaking of the securing pins in WD-40 (below left). |

|

|

|

|

||

| Fortunately a crane was available, on 29th March 2008, to assist with steadying the main rotor blades after detachment and with the subsequent lowering of the blades to the ground. After removal of these all-metal blades G-AVNE was rotated through 180 degrees before being pushed back into the conservation bay, nose-out and alongside the Wessex HAS.3, XM328, which had been in the new Engineering Hangar since mid-2007. | ||||

|

|

|

| In early April 2008 work started on removal of the covers for the main gearbox and transmission. Accumulations of dirt and birds' nests were removed to allow full checks on the condition of the deck and surrounding structures. | ||

|

|

|

| Initially it was thought that the tail cone should be separated from the main fuselage to allow work on both sections to be carried out more easily. The tail rotor drive shaft, control cables and wiring harnesses were disconnected appropriately but the idea was abandoned when it was realised that, in the absence of suitable substantial cradles, the stability of both sections would be seriously compromised after separation. | ||

|

|

|

| Later in April 2008 the tail rotor transmission drive shaft sections and the intermediate gearbox were removed, followed by the tail rotor head itself (above left). On 17th May 2008, after removal of remaining control rods and electric cabling, the hinged tail rotor pylon was detached from the tail cone and placed in a small, locally-built, cradle (above right). | ||

|

|

|

| It was known that there was corrosion in the transmission deck, so equipment surrounding the main gearbox (above left) was dismantled to allow better access. The worst corrosion was found (above right) below the mounting plate of the tail rotor drive shaft brake assembly, where the deck and cabin roof were penetrated. | ||

|

|

|

| Initial inspection of the cabin (above left), in April 2008, showed that the original furnishings and fittings were still in place and in good condition. First glances indicated that the interior airframe was sound, but when ceiling trim panels were removed it was clear that serious corrosion (above right) had taken hold, perhaps because of restricted ventilation. The many affected areas will be cleaned, treated, primed and repainted. | ||

|

|

|

| The main instrument panel appeared to be in good condition (above left), with a full set of instruments. However, closer examination showed that there were a lot of patches of light corrosion in the panel so, because it was also intended to clean and check each instrument, it was decided, in July 2008, that the panel would be removed, stripped, treated for corrosion and re-painted (above right). | ||

|

|

|

| The cockpit canopy (above left) was found to be weakened, with sections of severe corrosion. All the electrical cabling and other fittings were removed by the end of October 2008, so that the canopy could be lifted and, eventually, replaced with an unused spare canopy which has been in storage. The original doors from G-AVNE were in good condition and are being retained but better door frames have been obtained from a donor Wessex. Parts of the nose top structure, forward of the canopy, were showing severe skin corrosion. Replacement panels were fabricated and the structure beneath was treated and primed prior to repainting (above right). | ||

|

|

|

| The rear transmission platform on which the tail rotor drive shaft brake was mounted, suffering from severe corrosion beneath the brake assembly mounting plate, was removed from G-AVNE early in 2009 (above left). It had been decided, initially, that this deck should be replaced by one obtained from a donor Wessex, XR526. The donated platform was examined again and found to be in good condition but its mounting bolt locations did not match those on G-AVNE. A small portion of this platform was, therefore, cut out and grafted into the original deck, after refurbishment, to replace the corroded area. Some of the components removed from the platform were replaced and repainted (above right). Others were fitted after it had been returned to the fuselage. | ||

|

|

|

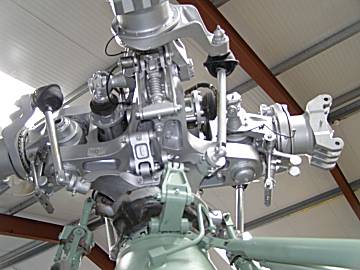

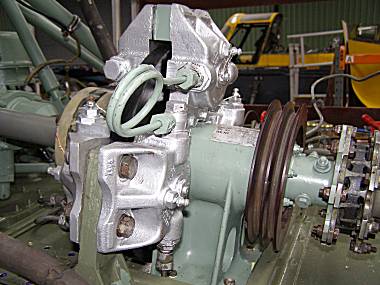

| By May 2009 G-AVNE's main gearbox and rotorhead were cleaned, refurbished and repainted. Being in relatively good condition and mounted on the forward transmission deck which was itself in a satisfactory condition, there had been no need to remove them. | ||

|

|

|

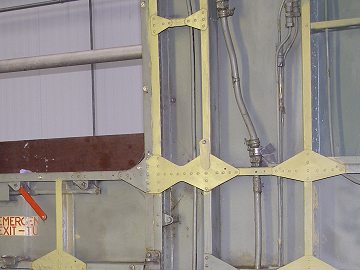

| Throughout 2009 work continued on the removal of corrosion on the cabin interior walls. The strengthening gussets, on the formers, were in especially bad condition (above left). After cleaning, an etch primer was applied, which chemically eats into the metal and bonds a thin coat of primer paint onto the surface (above right). A second coat of primer was often required before final painting took place. | ||

|

|

|

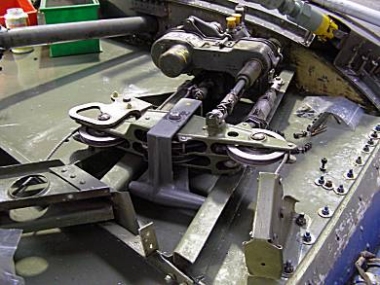

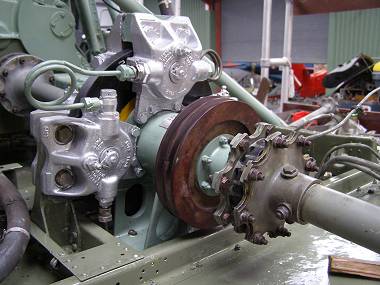

| In November 2009 the repaired rear transmission platform was painted and prepared (above left) for the refurbished tail rotor control servo assembly to be re-fitted on the port side (above right) in January 2010. | ||

|

|

|

| All corrosion was removed from the rotor brake assembly before it was painted and mounted on the new section of the rear transmission deck later in January 2010. | ||

|

|

|

| The replacement cockpit canopy, which had been in storage, was cleaned, masked and primed (above left) by the end of February 2010. After a final coat of blue paint had been applied, a Maeda mini crawler crane became available at short notice, on 7th April 2010. Before the canopy could be hoisted into place the refurbished instrument panel was lowered into position (above right) and partially installed by Mike and Stuart. | ||

|

|

|

| Minutes after installation of the instrument panel, on 7th April 2010, the cockpit canopy was raised, swung round and carefully lowered onto its fixing points. Once in place it took some time to position correctly due to slight dimensional differences. | ||

|

|

|

| One of the two auxiliary fuel tanks, situated behind the cabin rear bulkhead and above floor level, was cleared of corrosion and repainted in April 2010. A month later, on 29th May 2010, Stuart was preparing to replace the fibreglass louvred fairing above the tail rotor blade control servo and rear transmission deck. | ||

|

|

|

| Most of the extensive corrosion found on G-AVNE's cabin interior had been treated by the end of 2009 and painting was under way (above left) in June 2010. In mid-October 2010 Stuart (above right) was touching up the paintwork on the transmission deck ventilated fairing panels. | ||

|

|

|

| Team Leader Mike Reading (above) prepared to install the centralised warning indicator module in G-AVNE's cockpit instrument panel on 13th November 2010. | On a sparkling spring day in April 2011 the tail pylon was taken out of the hangar to be hosed down and cleaned (above) before inspection for corrosion. | |

|

|

|

| Work on G-AVNE's tail

pylon continued through Summer 2011, with several areas of minor to

severe corrosion to be tackled. In some cases the affected panels

had to be patched (above left), or replaced, before being primed and

repainted. Mike Reading started cleaning the air intake particle separator

swirl tubes in G-AVNE's nose door on 15th October 2011. |

||

|

|

|

| Photographed on 12 November 2011

when work was in progress to refurbish the pilot steps on the

port side of G-AVNE where corrosion had taken hold. |

||

|

|

|

| On 14th January 2012 G-AVNE's, partially restored, folding tail rotor pylon was hoisted upright and positioned to be reunited with the hinges on the rear end of the tail cone. | ||

|

|

|

| After thorough cleaning and refurbishment the tail rotorhead was reassembled (above left) and hoisted into place on the gearbox shaft at the top of the tail pylon (above right) in late April 2012. | ||

|

|

|

| Many hands make light work. Martin, Stuart and Mike remove a badly corroded panel from G-AVNE's horizontal stabiliser on 9th June 2012. | ||

|

|

|

| By the beginning of August 2012 G-AVNE's horizontal stabiliser (above left) had been repaired, stripped and primed ready for repainting while the four tail-rotor blades (above right) awaited refurbishment. | ||

|

|

|

| Stuart re-fitted the four newly-painted tail rotor blades on 16th February 2013 | Two weeks later the refurbished horizontal stabiliser was bolted in place on the tail rotor pylon. | |

|

|

|

|

|

|

| In early 2013 new volunteers, Keith and Roger, dismantled G-AVNE's main landing gear before refurbishing and repainting all the components. By mid-April 2013 re-assembly and refitting had started. Restoration continued, at a much slower pace, into 2018 and G-AVNE was finally rolled out of the Restoration Hangar in March 2019. | ||